Engineers avoid the EL backlight for new LCD Designs

Why engineers avoid the EL backlight for new LCD Designs

Below are seven reasons why the move from the EL backlight to LED backlights is being made on new product designs.

When designing new products, the majority of engineers are opting for a side-lit LED backlight display over EL (Electroluminescence), even though some LED (Light Emitting Diode) backlights may produce hot and cold spots.

Half-life:

EL backlight provides an estimated 3K hour half-life vs. the 50K to 90K hours provided by current LED technology. Longer half-life is important as most manufacturers no longer build products to be repaired.

Shorter half-life may not be an issue in some products where the backlight is only on for short periods of time or the product is disposable. An example of this is a portable glucose monitor, where the backlight is only on a few seconds a day.

What is a Half-Life? Half-life is the amount of time (in hours) before the backlight becomes half as bright compared to when it was first turned on. It is not the amount of time required for the backlight to completely go dark.

Inverters are out:

EL backlight requires an AC signal and most designs, including battery powered products, supply DC. This means an inverter is required. The additional components for an inverter circuit add to the overall cost of the product and also require additional real estate on the PCB that may already be overcrowded.

If the product needs to meet intrinsic design specifications, Inverters cannot be used since they may produce an ignition source. Intrinsic designs operate in environments, such as mines and factories, where flammable gasses may be present.

LEDs are DC driven and in many cases operate on the same voltage and current as the LCD logic, thereby reducing the number of power connections.

Brightness (intensity):

LED backlights are much brighter and have a greater intensity than the EL backlight. It is possible to build a LCD display with LEDs to achieve a brightness of 1,000 nits or higher.

What is a NIT? The brightness of the backlight is measured in ‘nits’. As a general rule, one nit = to the light produced by one candle. (It’s a bit more technical then that, but it works out the same)

Noise:

An AC signal can generate noise, an issue that may require the OEM to provide some type of shielding. This will not only increase the overall cost of the product, but may add complications when qualifying through some regulating agencies such as UL, CSA, etc.

MOQ:

Minimum Order Quantities (MOQ) for the EL backlight have increased from 100 to 1K in the last three years, and that number only looks to rise. A large number of products manufactured in the US have estimated usages of 200 units or less a year, a high MOQ makes it difficult to launch a product when you are required to purchase several years of inventory.

Another concern is for replacement/warranty work since a company may only repair a small number of units a year, but is forced to purchase 1K LCDs with EL backlight to hold in their warranty inventory.

In contrast LEDs are an off-the-shelf item with lower MOQ’s; which reduces lead-time when building prototype samples for alpha and beta test runs.

Dimming:

Dimming an LED backlight is much less complicated then dimming an EL backlight and can be accomplished through:

- User interface

- Software that monitors ambient light and adjust the brightness accordingly

- Replacing the current limiting resistor with a potentiometer (trimmer).

Dimming the backlight is important on battery powered products such as cell phones, portable test equipment and multiple other hand held products.

Limited size:

The El backlight is limited in size and cannot be integrated in larger displays such as monochrome QVGA (320×240) displays. In the past CCFL (Cold-Cathode Fluorescent Lamp) replaced EL backlights on larger displays, but CCFL displays have been discontinued due to environmental reasons (such as lead) and have been replaced with multi-LED arrays. LED backlights, however, are not a drop-in equivalent for CCFL since CCFL, like EL backlights, require an AC supply.

Multi-array LEDs (backlit, side-lit and edge-lit) have been able to provide a more even light flow thanks to better diffuser technology.

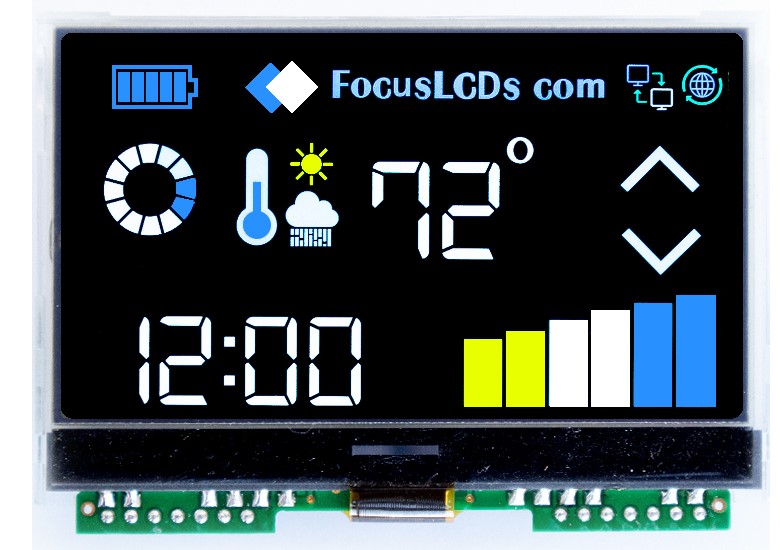

One challenge to the white LEDs as in the photo above is that if they are too bright, they can create hot spots or polka-dots on the LCD. The best solution to the elimination of hot-spots has been to reduce the brightness of each individual LED and increase the total number of LEDs.

Focus Display Solutions offers various technologies to reduce hot-spots to create a more uniform backlight.

Call us today at 480-503-4295 for US based technical LCD support; or fill out the Contact Form.